Custom Mold Making for LED Automotive Lighting: Challenges and Solutions

The automotive industry has seen rapid advancements, particularly in LED lighting, where precision and clarity are integral to performance and aesthetics. Custom mold making plays a vital role in creating high-quality LED lighting components, yet the process is not without its complexities. This blog explores the unique requirements, challenges, and solutions in mold making for LED automotive lighting to shed light on how industries can meet these demands efficiently.

Table of contents:

Specific Requirements for Molds in LED Automotive Lighting Production

Ensuring Optical Clarity in Injection Molded LED Lighting Parts

Overcoming Common Defects in LED Lighting Through Precision Molding

Specific Requirements for Molds in LED Automotive Lighting Production

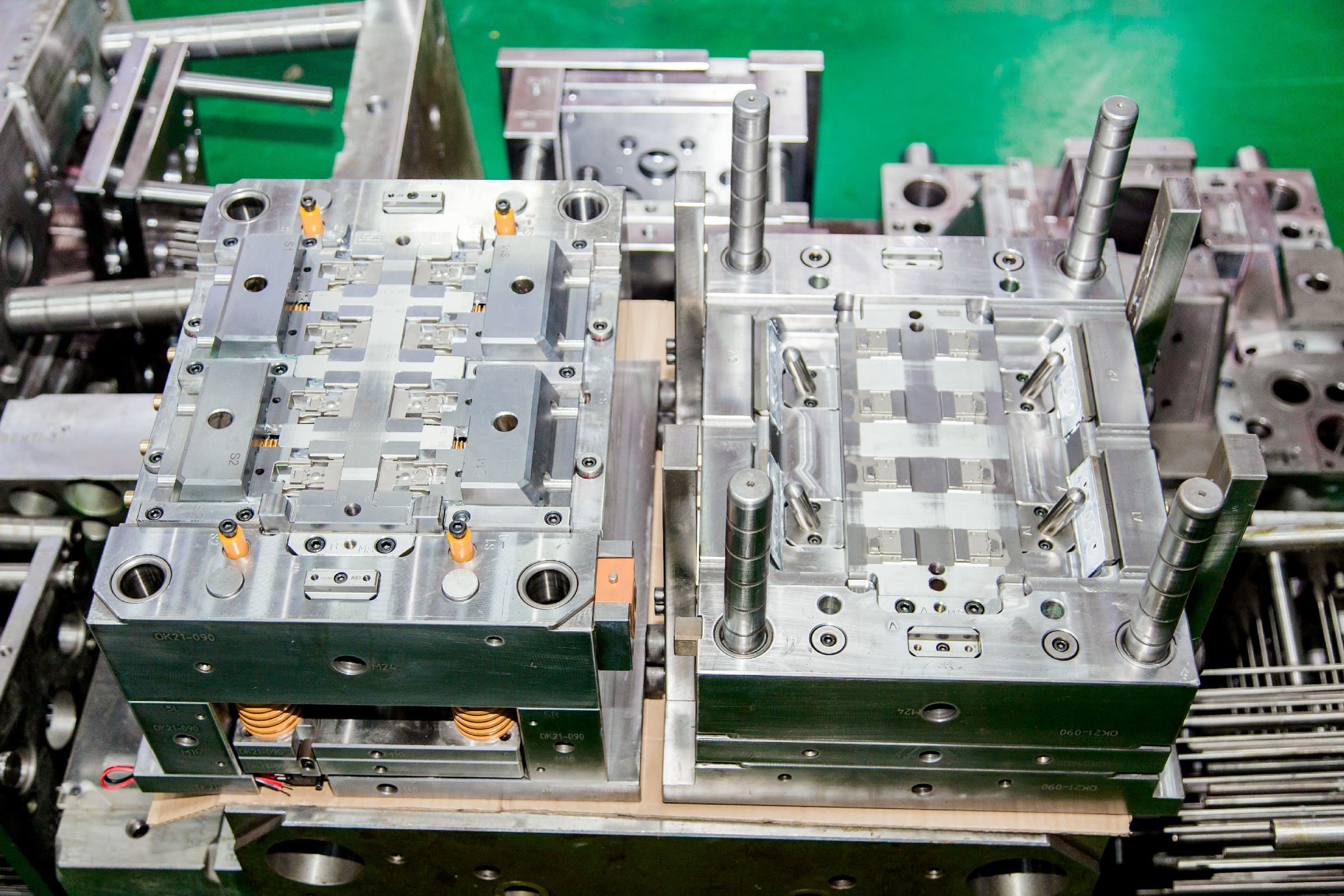

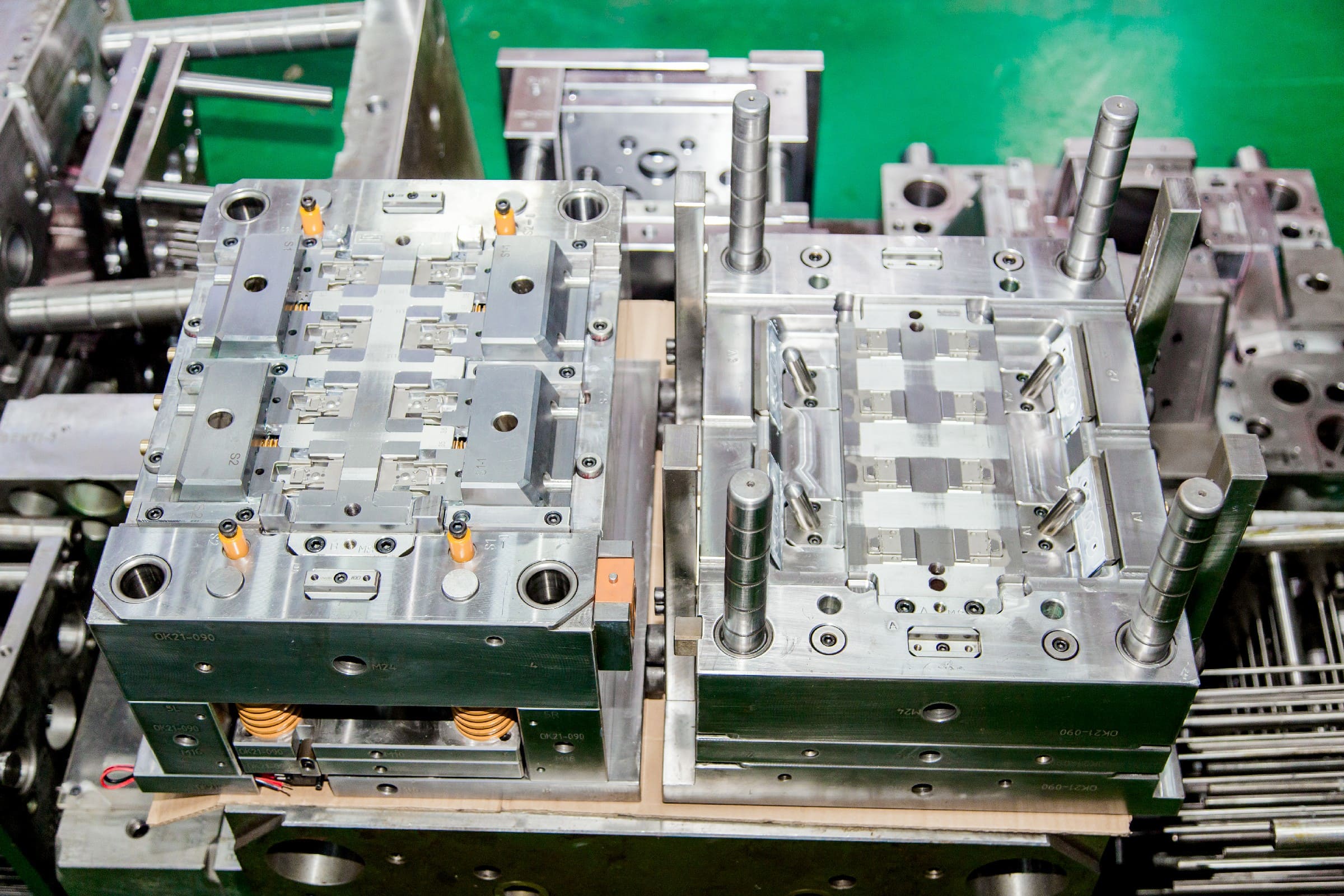

Producing LED automotive lighting parts requires molds that adhere to highly specific design and engineering requirements. Unlike traditional components, LED lighting demands intricate mold detailing to ensure the highest standard of optical precision. The first consideration is material compatibility; the mold needs to accommodate polycarbonate or acrylic materials, which are commonly used in the production of LED lenses due to their transparency and durability. Additionally, dimensional accuracy is essential. The slightest deviation can compromise the function of the lighting system, resulting in optical distortion or suboptimal illumination. Key to these specifics is the ability to handle complex geometric patterns without errors. This is where companies providing advanced custom mold making services, such as OKAY MOLD, bring value by offering tailored solutions to meet such exacting standards. Firms specializing in injection mold making also help streamline the production process, minimizing time delays without compromising quality.

Ensuring Optical Clarity in Injection Molded LED Lighting Parts

One of the biggest challenges in producing LED lighting components is maintaining optical clarity during the injection molding process. Lighting parts such as lenses must remain crystal-clear to transmit light effectively. Issues like surface imperfections or internal bubbles can deteriorate the material’s clarity, affecting the lamp's performance and visual appeal. Achieving this clarity calls for precision injection mold technology capable of reducing these imperfections. Custom mold design is also essential to eliminate weld lines or flow marks, which can result from uneven cooling or inadequate pressure distribution in standard mold designs. Using the best mold materials and coating techniques further ensures smooth finishes compatible with multiple lighting applications. Some of the solutions include heat-controlled molds to regulate temperature precisely, addressing cooling inconsistencies. This allows manufacturers to produce defect-free LED parts that enhance illumination without compromising on aesthetics. OKAY MOLD’s mold making services stand out because they are tailored to meet these functional and aesthetic demands, guaranteeing not only optical clarity but also long-lasting durability.

Overcoming Common Defects in LED Lighting Through Precision Molding

Despite the advancements in mold-making technology, defects remain a common hurdle when producing LED automotive lighting parts. Issues such as warping, shrinkage, and surface blemishes can occur due to improper mold design or inadequate operational parameters. Warping happens when cooling rates are inconsistent, while shrinkage can lead to misalignment of parts over time. Both scenarios can severely impact a vehicle's LED lighting performance and reliability. Using precision injection mold solutions is critical for overcoming such challenges. Techniques such as computer-aided mold flow simulation help identify potential problem areas before production starts, enabling precise temperature control and uniform material distribution to eliminate common defects. Additionally, the importance of durable mold materials cannot be overstated. High-quality metal molds offer better wear resistance, ensuring they can cope with the rigorous demands of mass production without quality degradation over time. By adopting modern solutions that address these pain points, OKAY MOLD remains at the forefront of delivering defect-free LED lighting components through advanced injection mold making services.

Custom mold making goes beyond creating physical molds; it bridges aesthetic and functional requirements in high-precision automotive lighting parts. Firms equipped with cutting-edge mold-making technology, such as OKAY MOLD, ensure outstanding product performance by addressing the unique challenges of design, material compatibility, optical clarity, and defect mitigation. This synergy between innovative practices and meticulous engineering guarantees that manufacturers deliver some of the industry’s most efficient and visually appealing LED products. Elevate your LED automotive lighting production by investing in high-quality mold-making services tailored to meet the highest standards of clarity and precision.