As a TS16949 certified plastic automotive mold manufacturer, we specialize in designing and manufacturing precision injection molds. Our expertise includes automotive interior trim, automotive air condition, automotive car door trim, new energy vehicle (NEV) battery parts and other automotive plastic components or parts that require advanced finishing like electroplating and coating parts. Our team is well-versed in PPAP processes and requirements. Contact us for a quote and free DFM.

Product Detailed Description:

1. CNC Precision Engineering for Flawless Interior Components

OKAY-MOLD’s interior trim products are built with cnc precision machining services and support from our in-house cnc machining companies. These processes ensure ultra-fine tolerances, symmetrical geometry, and seamless finishes, making the trims perfectly compatible with the aesthetics and dimensions of modern car interiors. As a leading precision cnc machining company, we apply strict quality control using precision cnc machining inc equipment to guarantee defect-free parts over high-volume runs.

2. Injection Molding Expertise for Durable and Stylish Interiors

Manufactured with the expertise of automotive plastic injection molding companies, our interior trim parts provide exceptional impact resistance and long-term aesthetic retention. Using robust engineering-grade resins like PC/ABS and PA6, our plastic molding injection companies techniques offer products that resist heat, UV light, and chemical exposure, ensuring a long-lasting showroom finish even under challenging conditions. As a trusted plastic car parts manufacturer, we prioritize strength, lightweight design, and surface uniformity in every molded component.

3. Custom Mold Making and Scalable Production Solutions

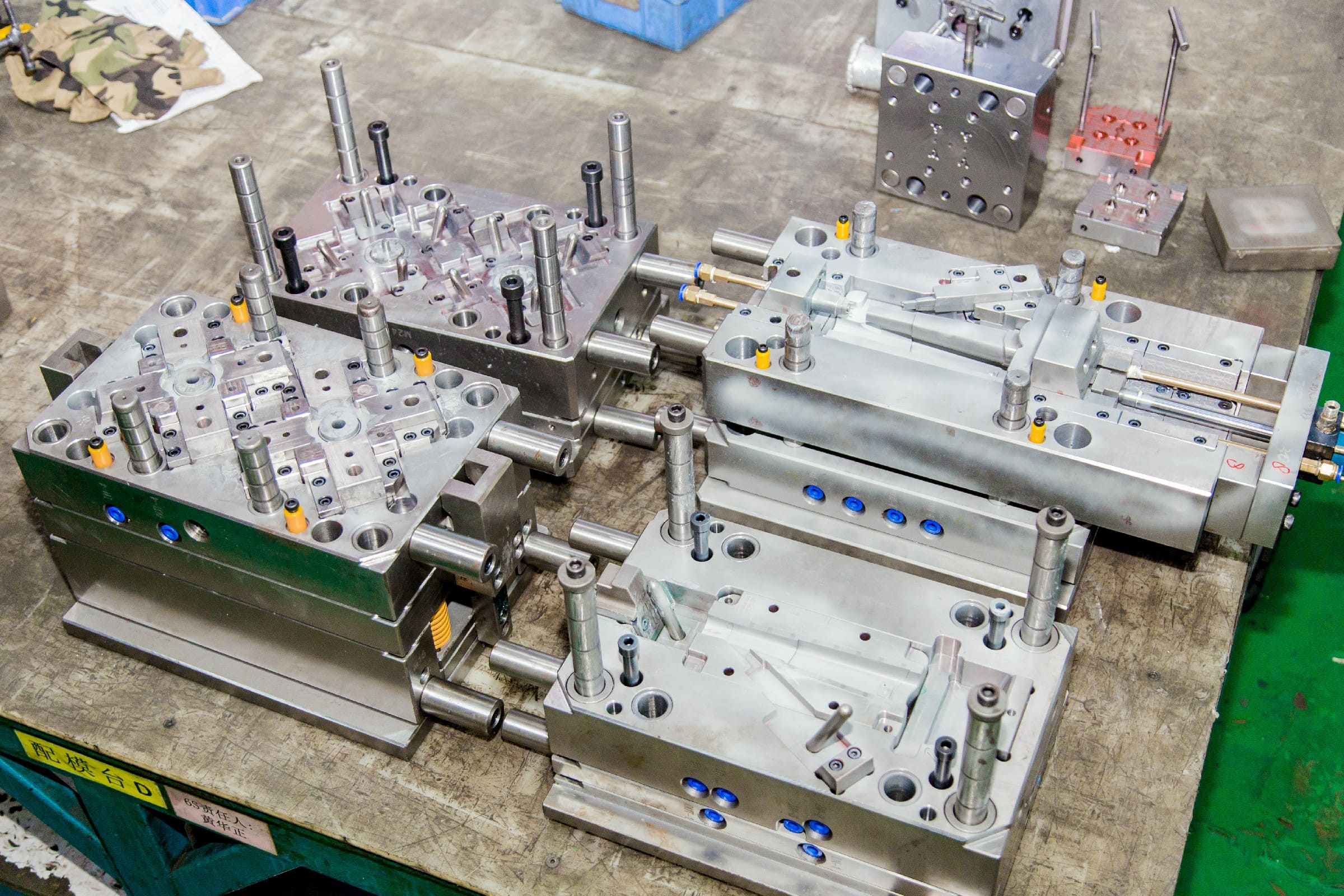

OKAY-MOLD provides complete custom mold making and mold making services to meet the highly customized needs of vehicle brands. We engineer molds to exact OEM standards using high-grade steel and apply mold flow simulations to optimize gate placement, cooling, and ejection. Our facility, as a certified plastic manufacturers in china, allows for fast prototyping, iterative design improvements, and rapid tool manufacturing to reduce lead times.

4. Fully Integrated Manufacturing for OEM-Level Quality

Our vertically integrated production system combines cnc plastic machining services, automated injection molding, and final part assembly. This enables strict process control from raw materials to packaging. As a globally recognized automotive plastic parts manufacturers partner, we use ERP-linked production lines, robotic handling systems, and real-time QA tracking to ensure high consistency, short cycle times, and fast global shipping.

5. Versatile Application Across Vehicle Models

Whether for dashboards, door trims, center consoles, glove boxes, or A/B/C pillar covers, our interior trim parts meet the diverse demands of modern car interiors. We tailor designs for various finishes—textured, gloss, matte, or painted—and incorporate options like ultrasonic welding or in-mold labeling. With support from our experienced cnc machining companies and plastic car parts manufacturer capabilities, we deliver market-ready solutions across a range of vehicle classes.

Product Features & Advantages:

a. High-Precision Manufacturing for Consistency: Using cnc precision machining services, cnc plastic machining services, and precision cnc machining inc, we deliver consistent, repeatable results that meet automotive assembly standards. Every piece is verified through inline metrology to ensure proper alignment and gap control.

b. Advanced Injection Molding with Performance Resins: Backed by automotive plastic injection molding companies and plastic molding injection companies, our interior trim is made from materials that offer superior surface aesthetics, low VOC emissions, and thermal deformation resistance—essential for climate-sensitive interior zones.

c. Flexible, Customized Tooling Options: Our full suite of custom mold making and mold making services enables both high-speed mass production and low-volume specialty runs. We offer interchangeable inserts, multi-shot mold systems, and collapsible cores to meet various part geometries and functional requirements.

d. Global-Grade Supply Chain & Logistics: As a leading plastic manufacturers in china and plastic car parts manufacturer, we operate efficient logistics that support just-in-time delivery, regional warehousing, and full traceability—ideal for global automotive procurement strategies.

e. Integrated Production for Cost & Time Savings: By controlling every step from mold design to final QC as automotive plastic parts manufacturers, we reduce outsourcing risk, lower cost-per-part, and shorten turnaround times. Combined with our cnc machining companies capabilities, this integration ensures lean manufacturing and high ROI.

Looking to source premium interior trim at wholesale prices? Contact OKAY-MOLD now for a competitive quote and secure your production start with a leading plastic car parts manufacturer and automotive plastic injection molding companies partner.

About Us - OKAY-MOLD

In the heart of Guangdong, China, OKAY-MOLD was founded with a clear mission: to provide precision mold making and plastic injection molding services that meet the highest standards of quality and efficiency. Over the years, we've expanded our expertise to include rapid tooling and comprehensive mold making solutions for various industries, including household electrical appliances, automotive and electric vehicles, office appliances, and beauty and health products.

Our commitment to excellence is reflected in our adherence to international quality management systems, such as ISO 9001:2008, ISO/TS 16949, and ISO 13485. We invest in state-of-the-art equipment from renowned manufacturers like Makino, Sodick, FANUC, and Sumitomo, ensuring precision and reliability in every project. Our dedicated team of professionals is passionate about delivering high-quality products with short lead times, consistently satisfying our international clientele.

Enter your email to hear from us about Product list, Latest Products and Customer application examples!