Common Challenges in Fan Furniture Mold Making and How to Solve Them

Designing and manufacturing custom plastic molds for fan furniture parts is a highly technical and precise process. A reliable custom plastic molds manufacturer plays a crucial role in producing durable and functional fan components, but manufacturers must overcome several challenges to ensure the final product meets exact specifications.From avoiding shrinkage and warping to choosing mold structures for curved parts, overcoming these challenges is essential for success in the field of custom mold making. Below, we’ll explore some of the common issues in fan furniture mold making and provide actionable solutions to tackle them effectively.

Table of contents:

Avoiding Shrinkage and Warping in Fan Plastic Parts

Tips for Ensuring High Repeatability in Mold Making Services

Choosing the Right Mold Structure for Curved Fan Parts

Avoiding Shrinkage and Warping in Fan Plastic Parts

One of the primary challenges in custom mold making for fan furniture parts is dealing with shrinkage and warping. When fan plastic parts cool and solidify, uneven cooling or improper material selection can lead to defects such as dimensional inaccuracies or visible distortions. To address this issue, manufacturers should consider the following solutions. First, selecting the appropriate type of plastic material that exhibits low shrinkage properties is critical.Second, ensuring uniform cooling throughout the mold cavity is vital to avoid warping. Optimizing the mold design by incorporating uniform wall thickness and efficient cooling channels can help distribute temperature evenly during the cooling process. Additionally, working with an experienced custom plastic molds manufacturer ensures that the mold is crafted with precision and tested to minimize distortions caused by shrinkage. By implementing these measures, mold making services can produce parts that maintain dimensional accuracy and aesthetic consistency.

Tips for Ensuring High Repeatability in Mold Making Services

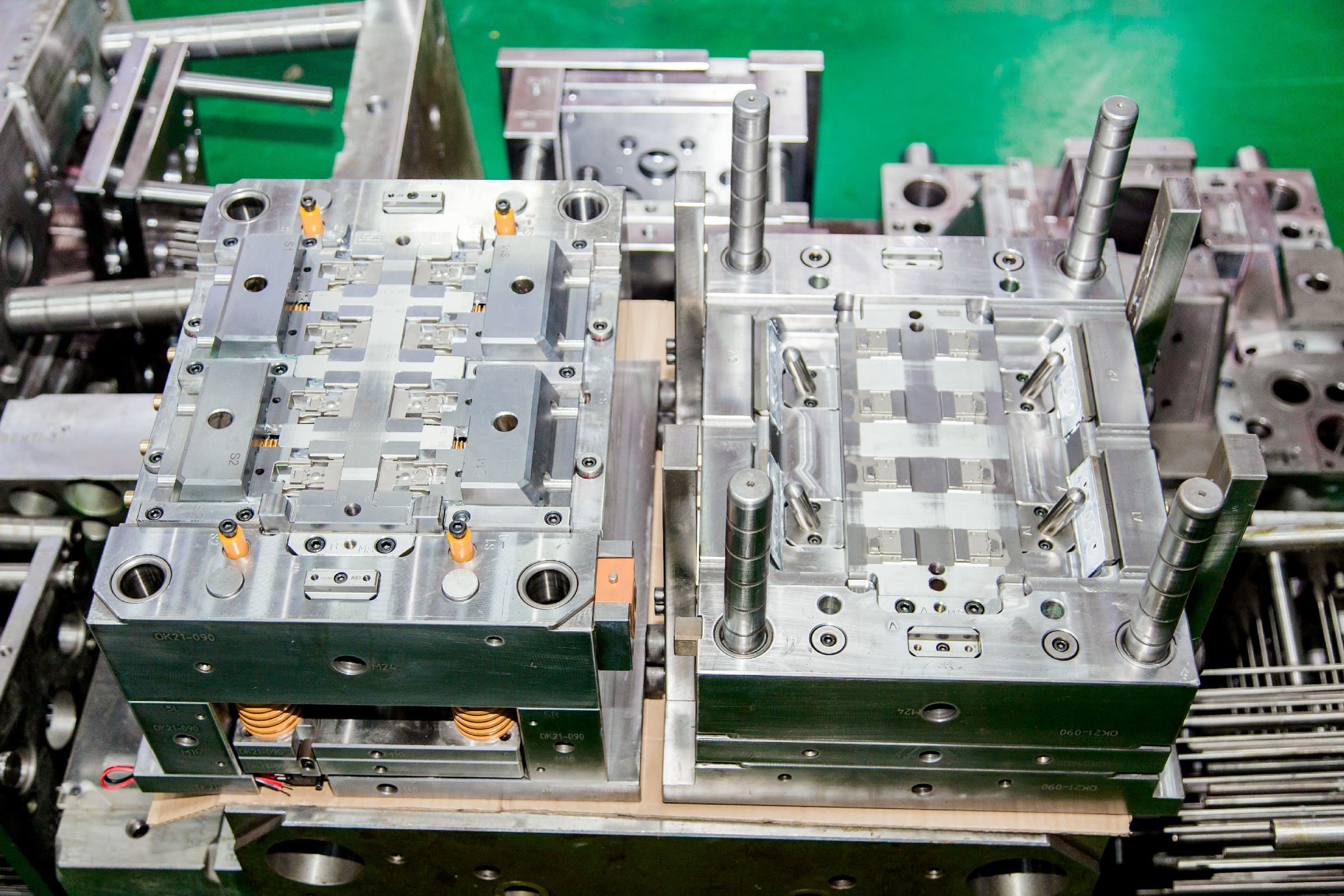

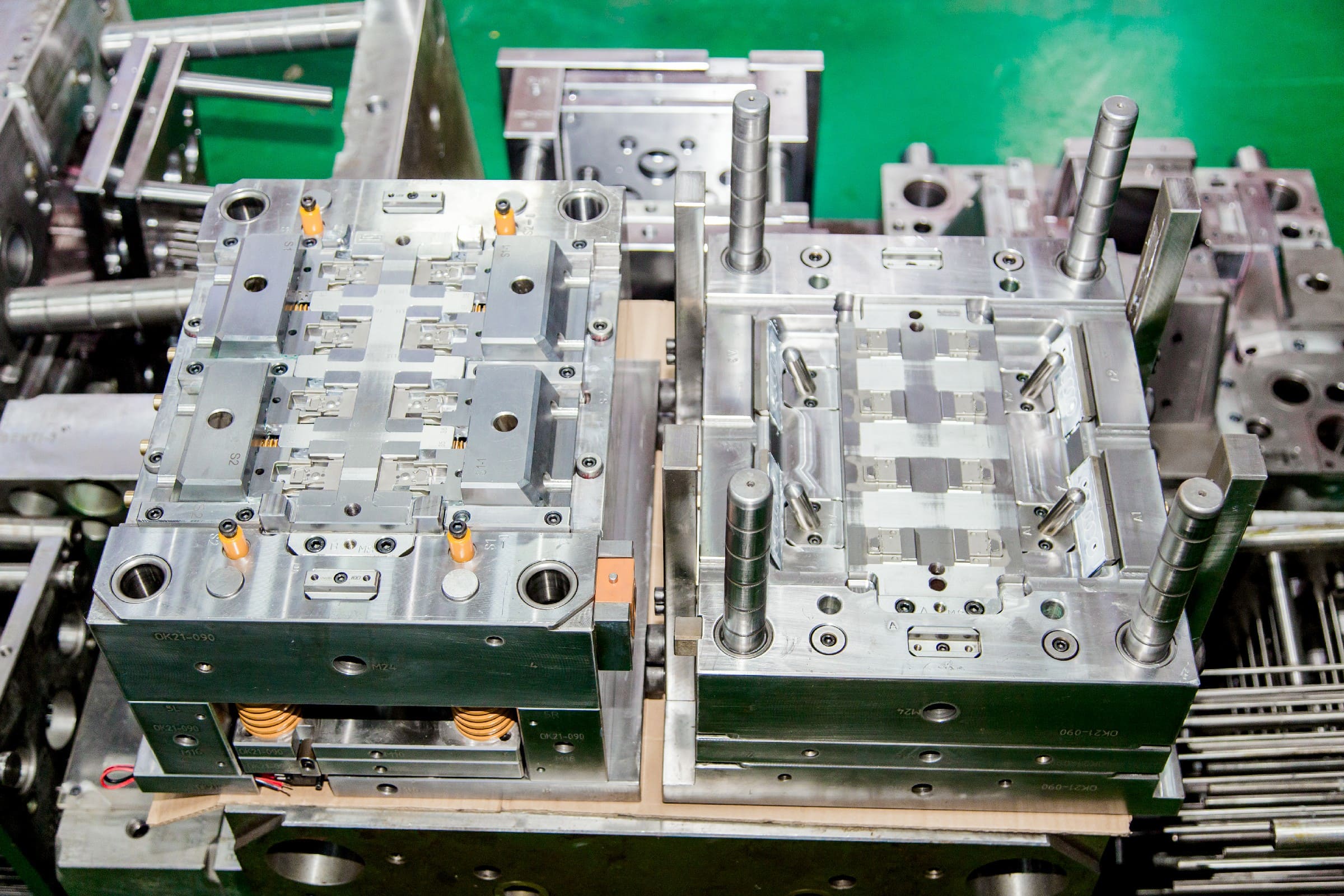

Repeatability is a crucial factor in custom mold making, especially for fan furniture parts that are produced in high volumes. Maintaining consistency in shape, size, and quality across multiple production cycles poses a significant challenge for many manufacturers. To achieve high repeatability, manufacturers must prioritize precision in mold design and tool machining. One effective approach is to use advanced computer-aided design (CAD) software to create detailed mold blueprints that minimize errors and align with specified tolerances. Additionally, utilizing Computer Numerical Control (CNC) machining technology ensures that each mold component is manufactured with high precision, reducing variations between parts. Another important aspect of ensuring repeatability is conducting routine mold maintenance. Regular cleaning, lubrication, and inspection of mold components prevent wear and tear that could compromise production quality. By focusing on these key strategies, businesses can enhance repeatability and reliability in their production processes, ensuring consistent quality, minimizing errors, and optimizing efficiency. This not only improves overall performance but also builds trust with customers and drives long-term success.

Choosing the Right Mold Structure for Curved Fan Parts

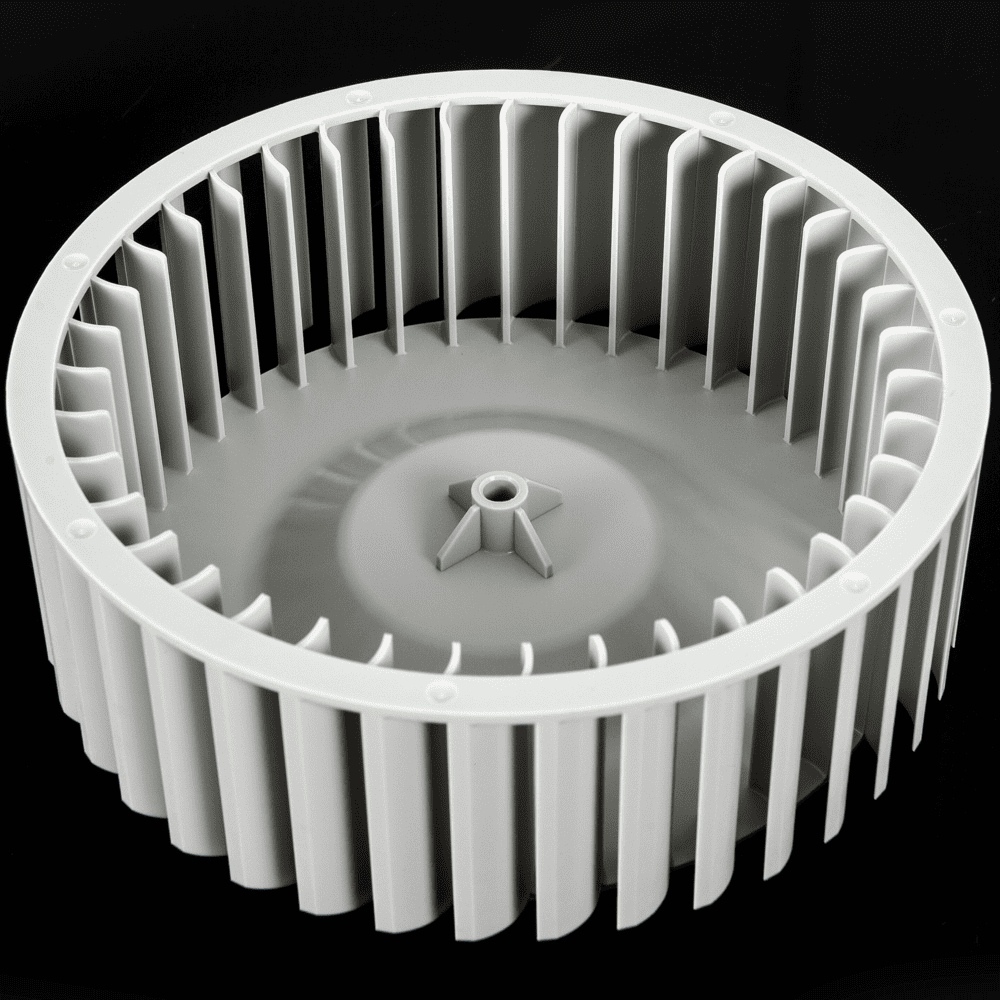

Designing molds for curved fan furniture parts introduces unique complexities that require careful consideration of mold structure. Curved parts, such as fan blades or back covers, often feature intricate geometries that demand innovative solutions to achieve precision and durability. Choosing the right mold structure is essential to overcome challenges associated with these features. A common solution is using multi-cavity molds, which allow for the simultaneous production of multiple identical curved parts, optimizing efficiency while maintaining uniformity. Additionally, incorporating sliding mechanisms or inserts into the mold design facilitates the production of complex curves without compromising structural integrity. Another key aspect is ensuring proper venting within the mold cavity to prevent air pockets or surface imperfections during the injection molding process. By carefully positioning vents around curved regions, manufacturers can achieve smooth and flawless finishes.Investing in the right mold structure not only enhances the quality of curved parts by ensuring precision and consistency but also improves overall production efficiency by reducing waste, minimizing errors, and speeding up manufacturing processes.

The precision and effectiveness of custom plastic molds play a pivotal role in the production of high-quality, intricately designed components. By leveraging advanced mold engineering techniques and collaborating with skilled manufacturers, businesses can achieve superior results that meet the demands of modern industries. Ultimately, investing in well-designed molds ensures not only exceptional product quality but also enhances manufacturing efficiency, positioning companies for long-term success.