The Role of Custom Mold Making in Durable Fan Component Production

The process of custom mold making has become essential for manufacturing durable fan components. As a household essential, fans rely on precision engineering and innovative techniques provided by a trusted custom plastic molds manufacturer to ensure reliability and durability. This blog explores the role of custom plastic molds in fan production, the advantages of mold-making services, and the materials and precision methods used to create long-lasting fan parts.

Table of contents:

What Makes Custom Plastic Molds Ideal for Fan Manufacturing?

How Mold Making Services Enhance Performance of Plastic Fan Parts

The Link Between Mold Precision and Fan Durability

Common Materials Used in Custom Molds for Fan Covers

What Makes Custom Plastic Molds Ideal for Fan Manufacturing?

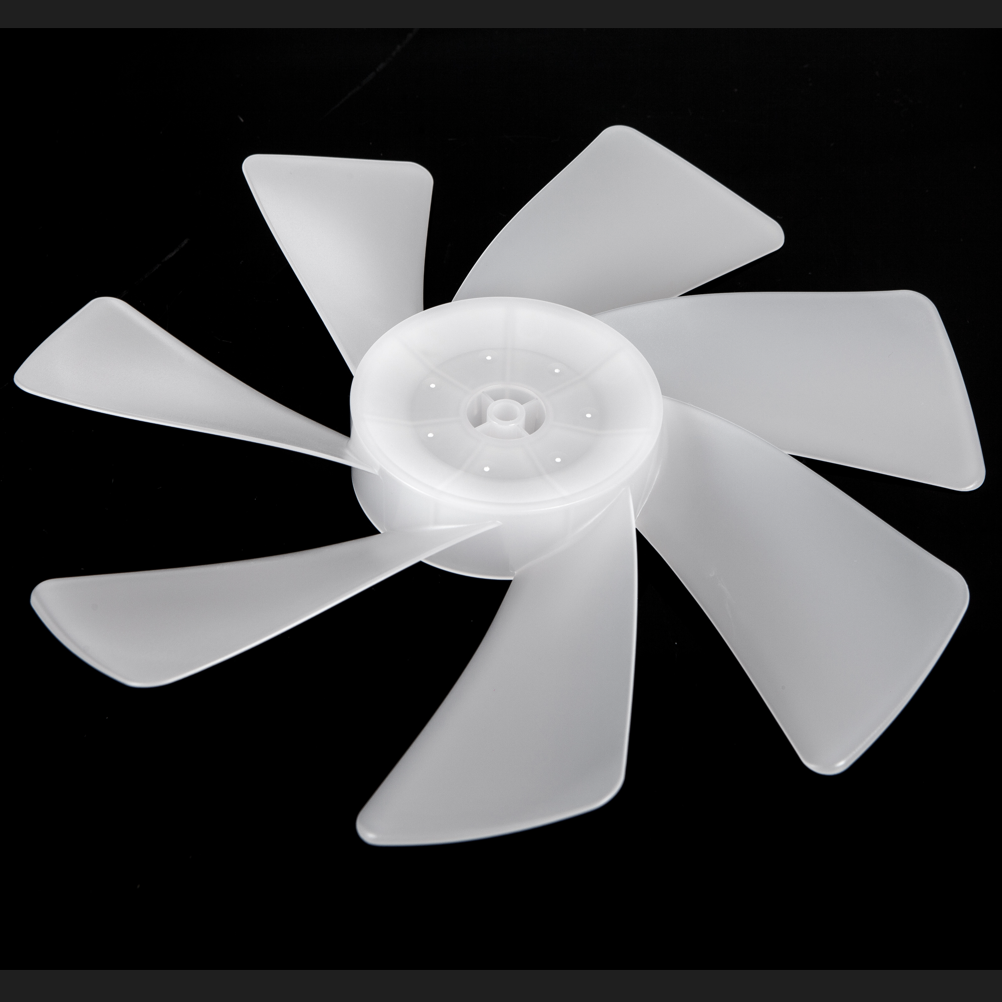

Custom plastic molds are designed to address the exact specifications needed in fan component production, including complex designs, detailed aesthetic finishes, and perfect dimensional accuracy. Unlike generic molds, custom molds allow manufacturers to tailor fan parts such as blades, back covers, and grills to specific designs, thus enhancing both functionality and appearance. With a high degree of customization, these molds ensure tighter fits and better performance for components, eliminating inconsistencies or imperfections in the manufacturing process. For lightweight and high-performance fan parts, manufacturers frequently turn to custom plastic molds to strike the ideal balance between durability and cost-efficiency. Importantly, custom molds offer repeatability, making them ideal for mass production while maintaining strict quality control.

How Mold Making Services Enhance Performance of Plastic Fan Parts

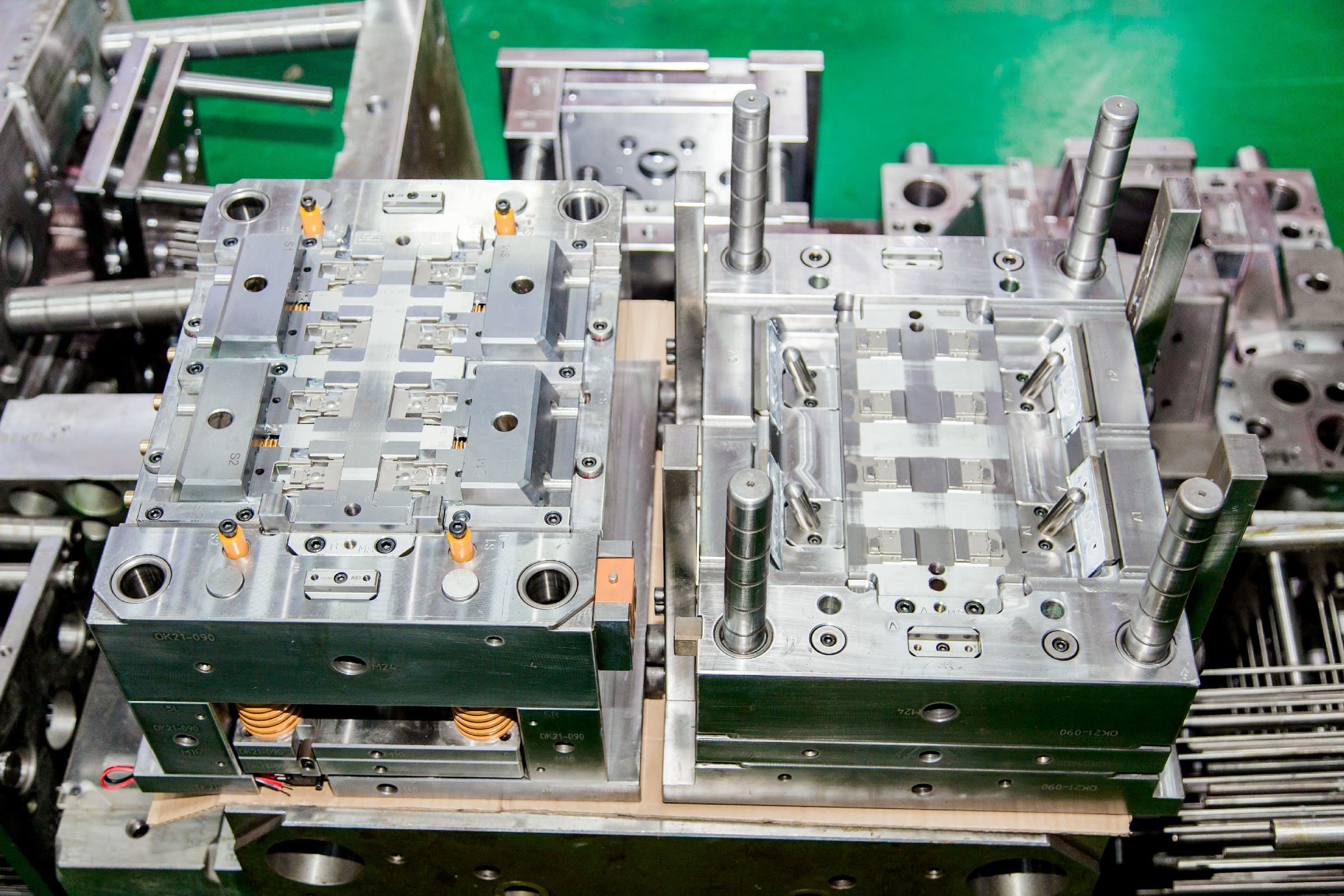

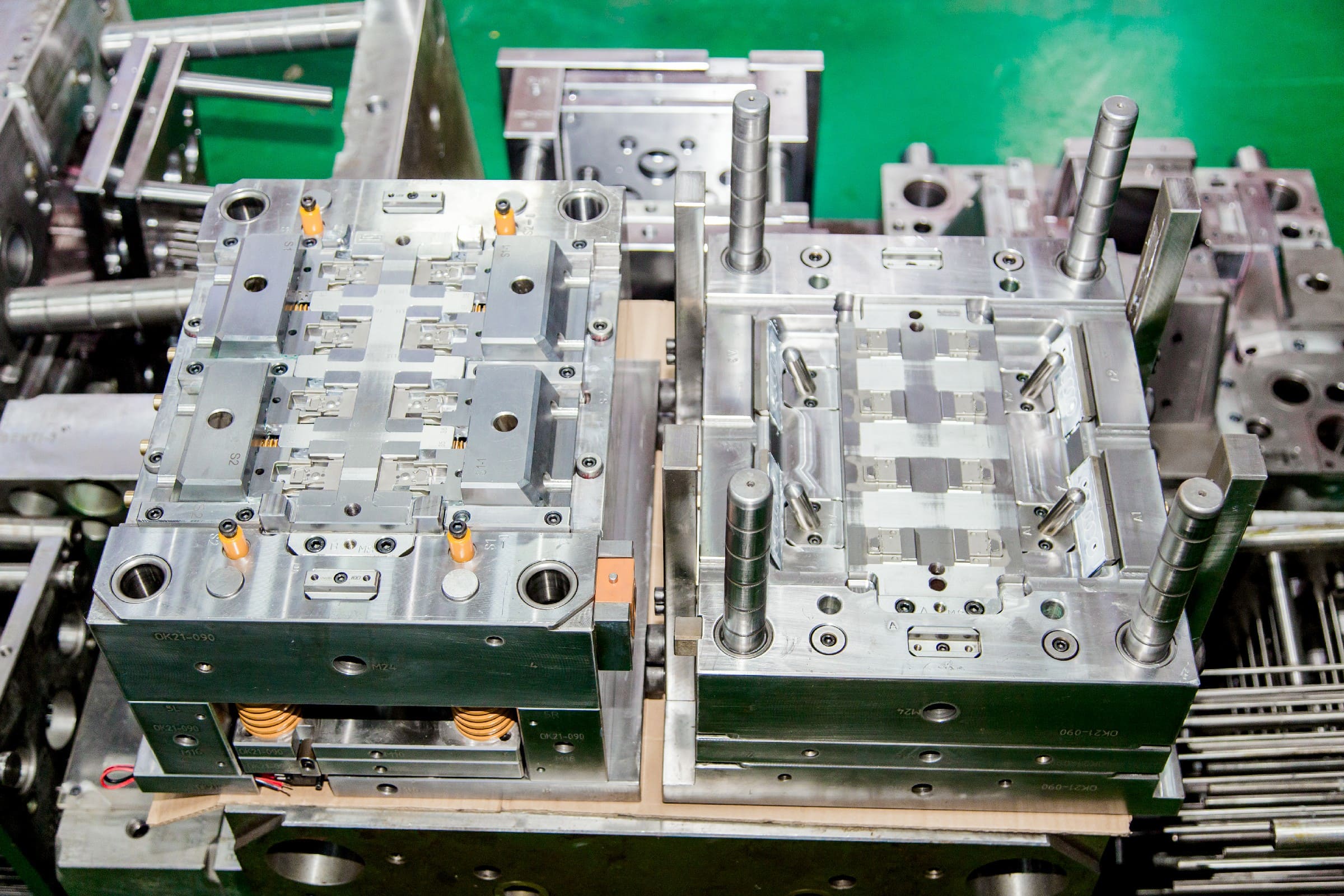

Mold making services offer advanced technologies, such as computer-aided design (CAD), precision CNC machining, and injection molding capabilities that enhance the performance of fan parts. The refined process of mold making ensures uniformity in the output, meaning that each fan component adheres to the same rigorous standard. By partnering with experienced manufacturers or mold making service providers, companies produce fan parts that deliver optimal airflow, minimize vibration, and reduce noise levels. Additionally, mold making services cut down on manufacturing errors, saving resources, reducing waste, and speeding up production timelines. The application of engineering principles and fine-tuned molds ensures that structural weaknesses, often responsible for product failure, are eliminated. Companies employing modern mold-making services also benefit from prototyping and iterative testing, guaranteeing each fan component meets or exceeds performance expectations.

The Link Between Mold Precision and Fan Durability

Precision is everything in custom mold making, and it directly impacts the durability of fan components. When molds are crafted with the highest accuracy, the resulting plastic parts exhibit excellent fit and alignment, which makes the fan more robust and extends its lifespan. Mold-makers utilize technologies such as high-speed CNC machines and 3D modeling to achieve a superior level of detail and exactness. This directly affects how components interlock or assemble seamlessly, which reduces wear and tear over time. For example, fan blades manufactured with precision molds are resilient to fatigue, minimizing the chances of cracking or distortion during operation. Similarly, precision-made back covers ensure proper assembly and protect the interior mechanisms of the fan, contributing to its durability under prolonged use. Therefore, the performance and reliability of a fan unit are deeply tied to the precision and expertise applied during mold production.

Common Materials Used in Custom Molds for Fan Covers

The choice of material in custom mold production is key to creating durable, high-performing fan parts. Common materials include ABS, polycarbonate, polypropylene, and sometimes polyethylene. ABS is widely used due to its lightweight, strength, rigidity, and impact resistance. Polycarbonate provides excellent transparency for polished aesthetics while maintaining structural integrity in tough conditions. Polypropylene is heat and chemical resistant, making it a stable choice for parts exposed to harsh environments. Engineering-grade polymers are also increasingly used for fan blades or covers, offering UV resistance, minimal thermal expansion, and crack resistance. Selecting the right material not only ensures durability but also boosts cost-effectiveness in mass production. Custom mold making, professional mold-making services, and working with experienced manufacturers are essential for producing high-quality, long-lasting fan components. By focusing on precision, material selection, and expert services, manufacturers can create advanced fan parts that deliver durability and efficiency throughout their lifecycle.

The development of modern fan components relies heavily on precision engineering and the expertise of custom mold manufacturers. By investing in high-quality mold-making services and selecting the right materials, manufacturers can achieve consistent performance, durability, and cost-efficiency. This approach not only enhances the overall quality of the final product but also ensures customer satisfaction and long-term reliability. Through continuous innovation and collaboration, the industry can meet the evolving demands of consumers while maintaining sustainable and efficient production practices.