Why Custom Plastic Molds Matter in Fan Furniture Manufacturing

Fan furniture manufacturing is a vital sector within the home appliance industry, and the role of custom plastic molds in this process is indispensable. From enhancing the design to improving production efficiency, custom mold making has transformed how fan components are created. This article explores how custom plastic molds influence fan furniture manufacturing, how they streamline large-scale production processes, how to choose the right custom plastic molds manufacturer, and how mold making services can save costs for businesses in this industry.

Table of contents:

The Impact of Custom Mold Making on Fan Back Cover Design

How Custom Plastic Molds Streamline Large-Volume Fan Parts Production

Choosing the Right Custom Plastic Molds Manufacturer for Fan Furniture

Cost-Efficiency of Mold Making Services in Home Appliance Components

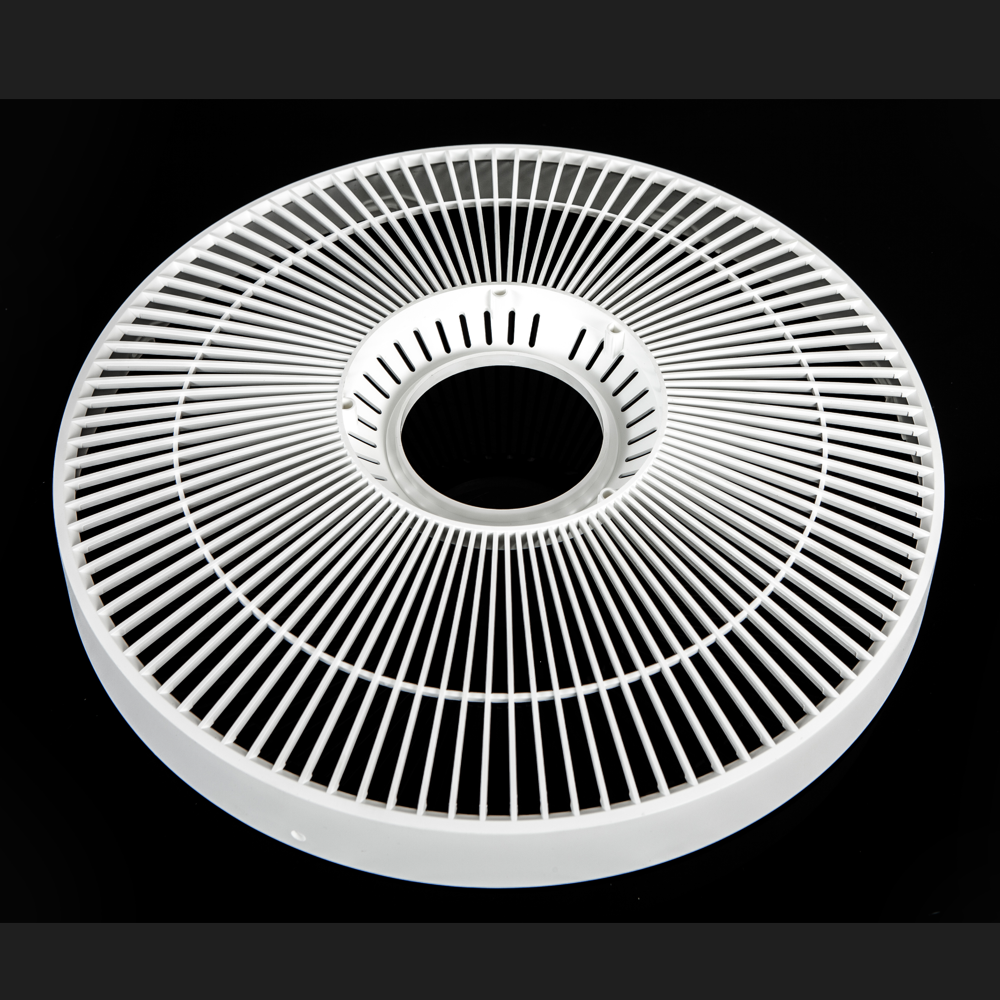

The Impact of Custom Mold Making on Fan Back Cover Design

Custom mold making plays a pivotal role in shaping fan back covers, which are integral to both the functionality and aesthetic appeal of fan furniture. Custom molds allow manufacturers to precisely design intricate features such as ventilation patterns, ergonomic adjustments, and unique textures that align with brand identity. Advanced molding techniques enable the production of back covers that not only look great but also enhance functionality by improving airflow and reducing operational noise. These techniques ensure precision and durability, creating covers that perform effectively while still maintaining a sleek aesthetic. Furthermore, the use of custom plastic molds allows for greater flexibility in design iterations, enabling manufacturers to experiment with innovative shapes, sizes, and features. This ensures that even the most complex and ambitious ideas can be transformed into high-quality, reliable fan back covers that meet both performance and design standards.

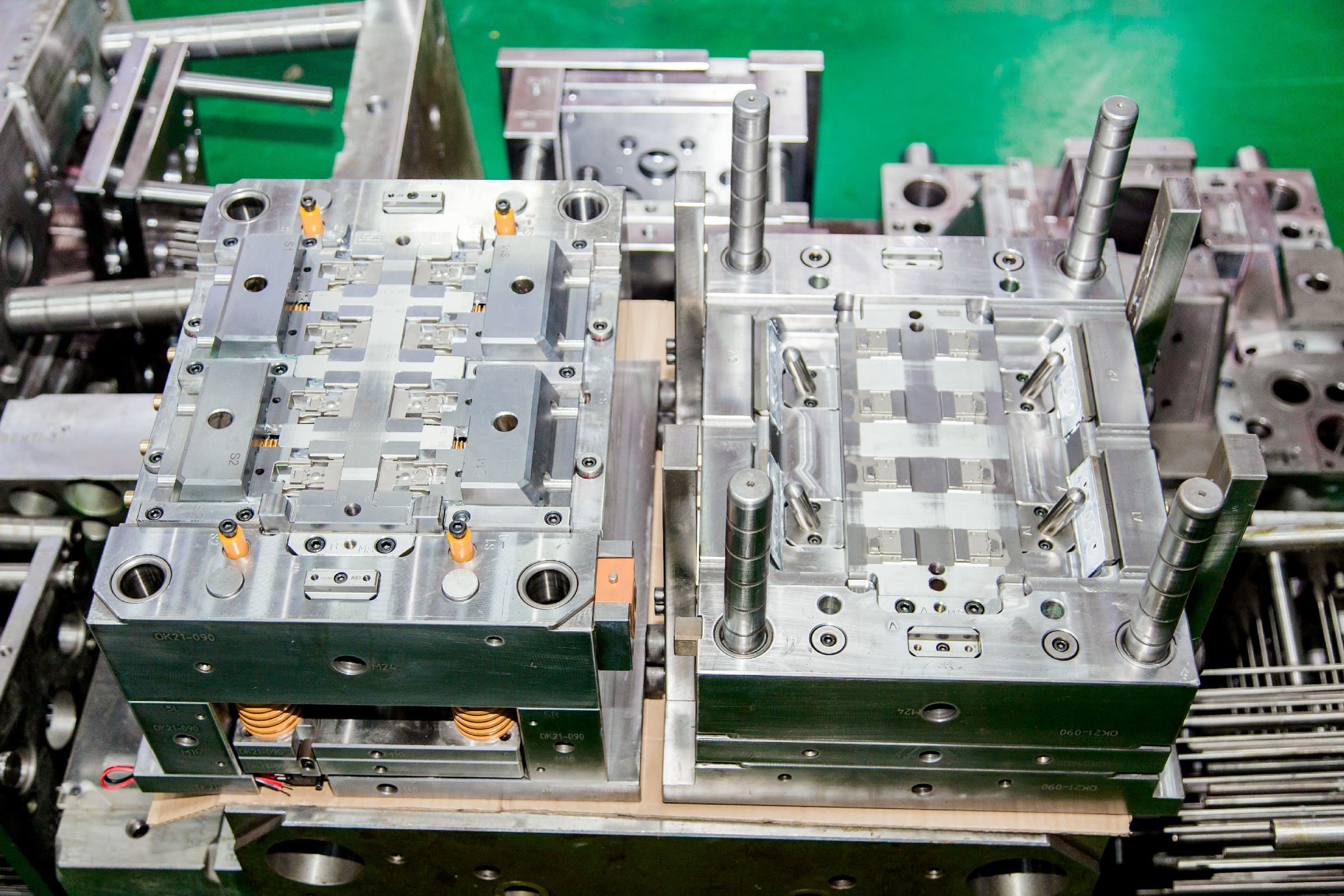

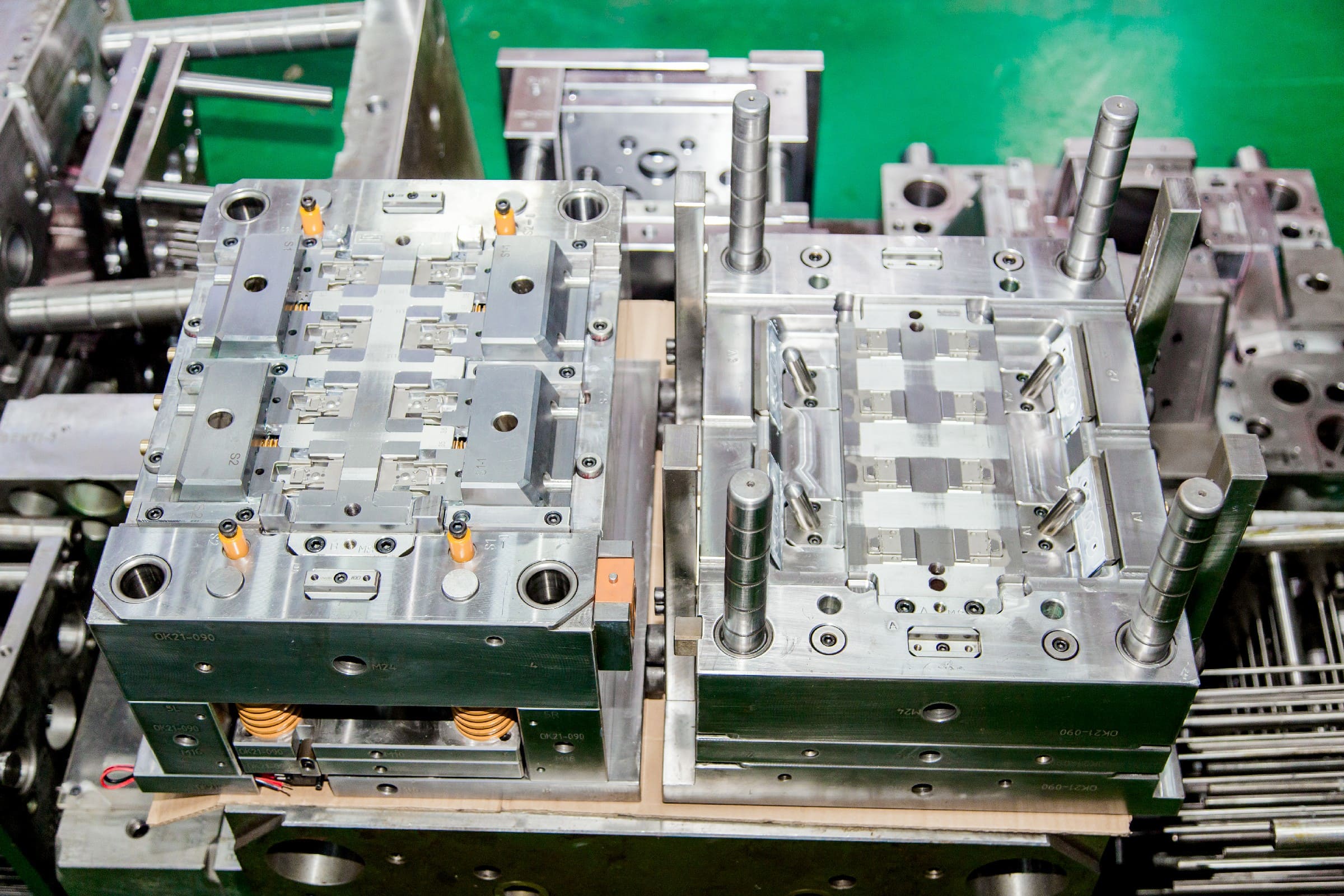

How Custom Plastic Molds Streamline Large-Volume Fan Parts Production

When manufacturing fan furniture on a large scale, efficiency and consistency are key to meeting high demand and maintaining quality. Custom plastic molds play a crucial role in streamlining the entire production process by enabling manufacturers to produce large volumes of fan components with exact uniformity. These molds are designed to ensure precise measurements and flawless replication across every piece, reducing errors and waste. By relying on custom molds, manufacturers can not only speed up production but also maintain a high standard of quality and durability in their products, ensuring customer satisfaction and long-term reliability.Utilizing high-quality molds minimizes defects, reduces material waste, and ensures tighter product tolerances. Additionally, modern mold making services often incorporate automation and advanced injection molding technology, dramatically cutting down production time. With the ability to manufacture components in bulk without compromising quality, manufacturers can meet growing market demands more effectively.

Choosing the Right Custom Plastic Molds Manufacturer for Fan Furniture

Selecting the right custom plastic molds manufacturer is critical for achieving optimal results in fan furniture manufacturing. A reliable manufacturer should have extensive experience in custom mold making and a proven track record of delivering high-quality molds tailored to specific requirements. Factors such as expertise in using advanced materials, adherence to industry standards, and the ability to meet deadlines are essential considerations. It is also vital to work with a manufacturer that offers mold making services suited to the unique challenges of fan furniture production, such as complex geometries and durable materials. Effective communication and collaboration throughout the design and production phases further ensure that the final molds align perfectly with your manufacturing objectives.

Cost-Efficiency of Mold Making Services in Home Appliance Components

One of the most significant advantages of using custom plastic molds is the cost efficiency they bring to fan furniture production. While the initial investment in high-quality molds may seem substantial, the long-term benefits far outweigh the costs. Custom mold making minimizes material waste, reduces the likelihood of defects, and lowers maintenance requirements, all of which contribute to significant savings over time. Additionally, the ability to produce large quantities of components with precision ensures that manufacturers can keep up with demand without incurring extra production costs. Working with a reputable custom plastic molds manufacturer also ensures that the molds are durable and capable of withstanding repeated use, further enhancing cost efficiency.

Leveraging custom plastic molds presents numerous advantages for manufacturers seeking improved efficiency, cost-effectiveness, and product quality. By investing in precise and durable molds, businesses can minimize waste, meet production demands, and maintain consistency across their products. Partnering with a trusted manufacturer not only ensures access to high-quality molds but also provides the expertise and reliability needed to meet your production goals. By leveraging precision-engineered molds tailored to your specific requirements, businesses can achieve greater efficiency, consistency, and product durability. This makes custom plastic molding an indispensable solution for modern production needs across industries, driving long-term success and staying competitive in an ever-evolving market.